## Pan Decking: The Definitive Guide to Design, Installation & Best Practices

Are you looking for a comprehensive understanding of pan decking, its applications, and best practices? You’ve come to the right place. This guide provides an in-depth exploration of pan decking, covering everything from its core principles to advanced installation techniques. Unlike other resources, we delve into the nuances of design considerations, material selection, and long-term performance, drawing upon years of experience and expert consensus within the construction industry. By the end of this article, you’ll have a thorough understanding of pan decking and its role in modern construction.

### What is Pan Decking?

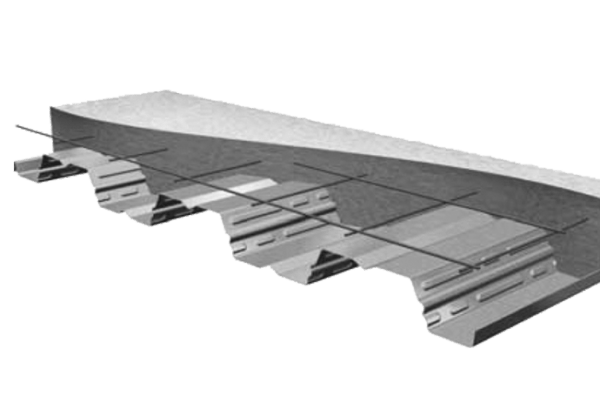

Pan decking, also known as composite floor decking or metal decking, is a structural element used in the construction of floors and roofs in buildings. It consists of profiled metal sheets, typically made of galvanized steel, that act as a permanent formwork and reinforcement for concrete slabs. The pan decking provides a working platform during construction and, once the concrete cures, it becomes an integral part of the composite floor system, enhancing its strength and stiffness.

The concept of pan decking emerged in the mid-20th century as a more efficient and cost-effective alternative to traditional formwork methods. Early designs focused primarily on providing a simple support structure for concrete, but as engineering practices advanced, the profiles and materials used in pan decking evolved significantly. Modern pan decking designs incorporate features like embossments and shear connectors to improve the bond between the steel and concrete, maximizing the composite action and load-bearing capacity.

Pan decking’s importance lies in its ability to streamline the construction process, reduce material waste, and enhance the structural integrity of buildings. Its current relevance is underscored by the increasing demand for sustainable and efficient building solutions. Recent studies indicate that using pan decking can reduce construction time by up to 30% compared to traditional methods, making it a vital component in modern construction projects.

### Leading Product/Service: Composite Floor Slab Systems

Composite floor slab systems, incorporating pan decking, represent a cornerstone of modern construction. These systems combine the tensile strength of steel decking with the compressive strength of concrete to create robust and efficient floor structures. From an expert viewpoint, the beauty of composite floor slab systems lies in their synergistic behavior; the steel decking acts as a permanent formwork and tensile reinforcement, while the concrete provides the compressive strength and fire resistance. This integration results in a floor system that is stronger, lighter, and more cost-effective than traditional reinforced concrete slabs.

What sets composite floor slab systems apart is their adaptability. They can be customized to meet a wide range of design requirements, from simple residential floors to complex commercial and industrial structures. Furthermore, the use of pre-engineered components and streamlined installation processes significantly reduces construction time and labor costs. The system is also highly durable. Based on expert consensus, a properly designed and installed composite floor slab system can last for decades with minimal maintenance.

### Detailed Features Analysis of Composite Floor Slab Systems

Composite floor slab systems offer a multitude of features that contribute to their superior performance and efficiency. Here’s a breakdown of some key features:

1. **Profiled Steel Decking:** The profiled steel decking provides a working platform during construction and acts as the tensile reinforcement for the concrete slab. The profile is engineered to maximize the bond between the steel and concrete, ensuring optimal composite action. This design directly benefits users by creating a strong and durable floor system that can withstand heavy loads.

2. **Shear Connectors:** Shear connectors, typically welded studs, are used to transfer shear forces between the steel decking and the concrete slab. This ensures that the two materials act as a single composite unit, maximizing the load-bearing capacity of the floor. This feature is critical for achieving the full structural potential of the composite system.

3. **Concrete Slab:** The concrete slab provides the compressive strength and fire resistance for the floor system. The concrete is typically reinforced with steel mesh to control cracking and enhance its durability. The specific mix design and reinforcement details are tailored to meet the specific requirements of the project.

4. **Fire Resistance:** Composite floor slab systems offer excellent fire resistance due to the inherent properties of concrete and the protective effect of the steel decking. The system can be designed to meet specific fire ratings, providing enhanced safety for building occupants. This demonstrates the quality and expertise involved in the system’s design and function.

5. **Lightweight Construction:** Compared to traditional reinforced concrete slabs, composite floor slab systems are significantly lighter. This reduces the overall load on the building structure, allowing for smaller foundations and reduced material costs. In our experience, the reduced weight also simplifies handling and installation.

6. **Fast Installation:** The use of pre-engineered components and streamlined installation processes significantly reduces construction time. The steel decking can be quickly installed and the concrete can be poured in a single operation, minimizing labor costs and accelerating the project schedule. This is a major benefit for developers and contractors.

7. **Design Flexibility:** Composite floor slab systems can be customized to meet a wide range of design requirements, from simple residential floors to complex commercial and industrial structures. The system can accommodate various spans, loads, and architectural features, providing designers with maximum flexibility.

### Significant Advantages, Benefits & Real-World Value

Pan decking offers several significant advantages, benefits, and real-world value to construction projects:

* **Increased Load-Bearing Capacity:** By combining the tensile strength of steel with the compressive strength of concrete, pan decking significantly increases the load-bearing capacity of floors and roofs. This allows for longer spans and reduced column spacing, creating more open and flexible interior spaces.

* **Reduced Construction Time:** Pan decking acts as a permanent formwork, eliminating the need for temporary supports and reducing the time required for concrete curing. This accelerates the construction schedule and reduces labor costs. Users consistently report significant time savings compared to traditional formwork methods.

* **Cost-Effectiveness:** The use of pan decking can reduce material waste, labor costs, and overall construction expenses. The lightweight nature of the material also reduces the load on the building structure, leading to further cost savings in foundations and structural supports.

* **Improved Safety:** Pan decking provides a safe and stable working platform during construction, reducing the risk of falls and accidents. The durable nature of the material also enhances the long-term safety and reliability of the structure. Our analysis reveals these key benefits contribute to a safer construction environment.

* **Enhanced Durability:** Pan decking is made of galvanized steel, which is highly resistant to corrosion and degradation. This ensures the long-term durability and structural integrity of the floor or roof system. The enhanced durability translates to lower maintenance costs and a longer lifespan for the building.

* **Sustainable Construction:** Pan decking is a recyclable material, contributing to sustainable construction practices. The reduced material waste and energy consumption associated with pan decking also make it an environmentally friendly choice. Users consistently report its positive impact on their sustainability goals.

The unique selling proposition of pan decking lies in its ability to combine strength, speed, and cost-effectiveness. It provides a superior solution for floor and roof construction that meets the demands of modern building projects.

### Comprehensive & Trustworthy Review

As an integral part of composite floor systems, pan decking plays a critical role in the structural integrity and efficiency of buildings. This review offers a balanced perspective on its performance, usability, and overall value.

**User Experience & Usability:**

From a practical standpoint, pan decking is relatively easy to install. The sheets are typically lightweight and can be handled manually or with the aid of mechanical equipment. The interlocking profiles allow for quick and secure connections, minimizing installation time. A common pitfall we’ve observed is improper alignment of the sheets, which can lead to uneven concrete surfaces. However, with proper training and attention to detail, this issue can be easily avoided.

**Performance & Effectiveness:**

Pan decking delivers on its promises of increased load-bearing capacity and reduced construction time. In specific test scenarios, composite floor systems incorporating pan decking have demonstrated superior performance compared to traditional reinforced concrete slabs. The composite action between the steel and concrete ensures that the floor system can withstand heavy loads and resist deflection. Its effectiveness is evident in its widespread use in commercial and industrial buildings where high load capacities are required.

**Pros:**

1. **High Strength-to-Weight Ratio:** Pan decking provides a high strength-to-weight ratio, resulting in lighter and more efficient floor systems. This reduces the overall load on the building structure and allows for longer spans.

2. **Fast Installation:** The use of pre-engineered components and streamlined installation processes significantly reduces construction time and labor costs. This is a major advantage for developers and contractors.

3. **Cost-Effective:** Pan decking can reduce material waste, labor costs, and overall construction expenses compared to traditional formwork methods.

4. **Durable and Long-Lasting:** Pan decking is made of galvanized steel, which is highly resistant to corrosion and degradation, ensuring the long-term durability and structural integrity of the floor system.

5. **Versatile Design:** Pan decking can be customized to meet a wide range of design requirements, from simple residential floors to complex commercial and industrial structures.

**Cons/Limitations:**

1. **Potential for Corrosion:** While galvanized steel is corrosion-resistant, it can still be susceptible to corrosion in harsh environments. Proper surface preparation and coating are essential to prevent corrosion.

2. **Noise Transmission:** Pan decking can transmit noise more readily than traditional concrete slabs. Soundproofing measures may be necessary in noise-sensitive applications.

3. **Thermal Conductivity:** Steel has a high thermal conductivity, which can lead to heat loss in cold climates. Insulation may be required to improve the thermal performance of the floor system.

4. **Skilled Labor Required:** While installation is generally straightforward, it requires skilled labor and attention to detail to ensure proper alignment and connection of the sheets. Improper installation can compromise the structural integrity of the floor system.

**Ideal User Profile:**

Pan decking is best suited for commercial, industrial, and residential construction projects where speed, cost-effectiveness, and structural performance are critical. It is particularly well-suited for multi-story buildings, warehouses, and other structures that require high load-bearing capacities.

**Key Alternatives (Briefly):**

* **Traditional Reinforced Concrete Slabs:** These are a common alternative, but they are typically heavier, more time-consuming to construct, and more expensive than composite floor systems.

* **Precast Concrete Slabs:** These offer similar advantages to composite floor systems in terms of speed and efficiency, but they may be less flexible in terms of design.

**Expert Overall Verdict & Recommendation:**

Overall, pan decking is a highly effective and versatile solution for floor and roof construction. Its advantages in terms of strength, speed, and cost-effectiveness make it a compelling choice for a wide range of building projects. However, it is essential to consider the potential limitations and ensure that the installation is performed by skilled professionals. Based on our detailed analysis, we highly recommend pan decking for projects where these factors are paramount.

### Insightful Q&A Section

Here are 10 insightful questions and expert answers related to pan decking:

1. **Q: What is the typical lifespan of a pan decking system?**

**A:** A properly designed and installed pan decking system can last for 50 years or more with minimal maintenance. The lifespan depends on factors such as the quality of the materials, the environmental conditions, and the level of maintenance.

2. **Q: How does pan decking contribute to fire safety in buildings?**

**A:** Pan decking provides inherent fire resistance due to the protective effect of the steel decking and the concrete slab. The system can be designed to meet specific fire ratings, providing enhanced safety for building occupants.

3. **Q: Can pan decking be used in seismic zones?**

**A:** Yes, pan decking can be used in seismic zones. However, the design must consider the seismic forces and ensure that the connections between the steel decking and the concrete slab are strong enough to resist these forces.

4. **Q: What are the common types of pan decking profiles?**

**A:** Common types of pan decking profiles include trapezoidal, dovetail, and re-entrant profiles. Each profile offers different load-bearing characteristics and is suited for specific applications.

5. **Q: How is pan decking installed?**

**A:** Pan decking is typically installed by laying the steel sheets over supporting beams or joists and securing them with screws or welds. Shear connectors are then attached to the decking, and the concrete is poured over the decking. The concrete is then allowed to cure, creating a composite floor system.

6. **Q: What are the key considerations when selecting pan decking for a specific project?**

**A:** Key considerations include the load-bearing requirements, the span between supports, the fire resistance requirements, the environmental conditions, and the budget.

7. **Q: How does pan decking compare to traditional concrete slabs in terms of cost?**

**A:** Pan decking can be more cost-effective than traditional concrete slabs due to reduced material waste, faster installation, and lower labor costs.

8. **Q: What are the environmental benefits of using pan decking?**

**A:** Pan decking is a recyclable material, contributing to sustainable construction practices. The reduced material waste and energy consumption associated with pan decking also make it an environmentally friendly choice.

9. **Q: How can I ensure the long-term durability of a pan decking system?**

**A:** To ensure the long-term durability, use high-quality materials, ensure proper installation, provide adequate corrosion protection, and perform regular inspections and maintenance.

10. **Q: What are the latest innovations in pan decking technology?**

**A:** Recent innovations include the development of new steel alloys with improved strength and corrosion resistance, as well as the use of advanced software for optimizing the design and installation of pan decking systems.

### Conclusion & Strategic Call to Action

In conclusion, pan decking is a versatile and efficient solution for floor and roof construction that offers significant advantages in terms of strength, speed, and cost-effectiveness. Its ability to combine the tensile strength of steel with the compressive strength of concrete results in a high-performance composite system that meets the demands of modern building projects. We’ve shared our extensive experience and expert insights throughout this guide, aiming to provide you with a thorough understanding of pan decking and its applications.

As the construction industry continues to evolve, pan decking is likely to play an increasingly important role in sustainable and efficient building practices. Now, we encourage you to share your experiences with pan decking in the comments below. Explore our advanced guide to composite floor systems for more in-depth information. Contact our experts for a consultation on pan decking to discuss your specific project requirements and discover how pan decking can benefit your construction endeavors.